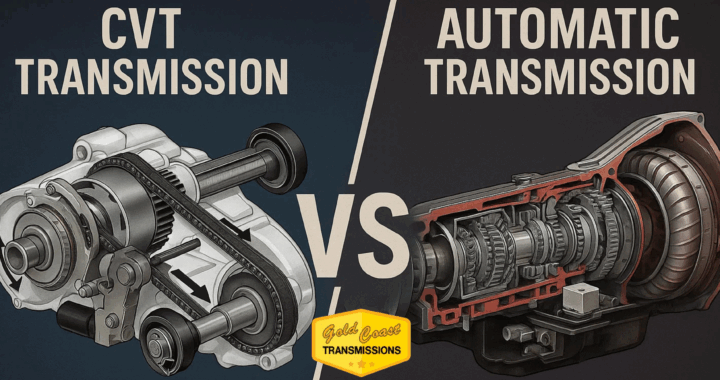

From the moment a customer describes a shifting issue, the type of automatic transmission in their vehicle—be it a conventional gear-driven automatic or a Continuously Variable Transmission (CVT)—sets the stage for a very different repair process in our shop. It’s worth noting that CVTs are automatics too; they just achieve their “automatic” operation in a different way. Instead of shifting through fixed gear ratios like a traditional automatic, a CVT adjusts seamlessly through pulleys and a belt or chain.

Under the Hood: A Tale of Two Transmissions

A traditional automatic transmission is a marvel of hydraulic and mechanical engineering, utilizing a complex system of planetary gearsets, clutches, and bands to deliver a set number of gear ratios. Think of it as a sophisticated bicycle gear system that shifts on its own. Our technicians are well-versed in the intricate dance of these components, and years of experience have made diagnosing and repairing them a familiar, albeit sometimes complex, process.

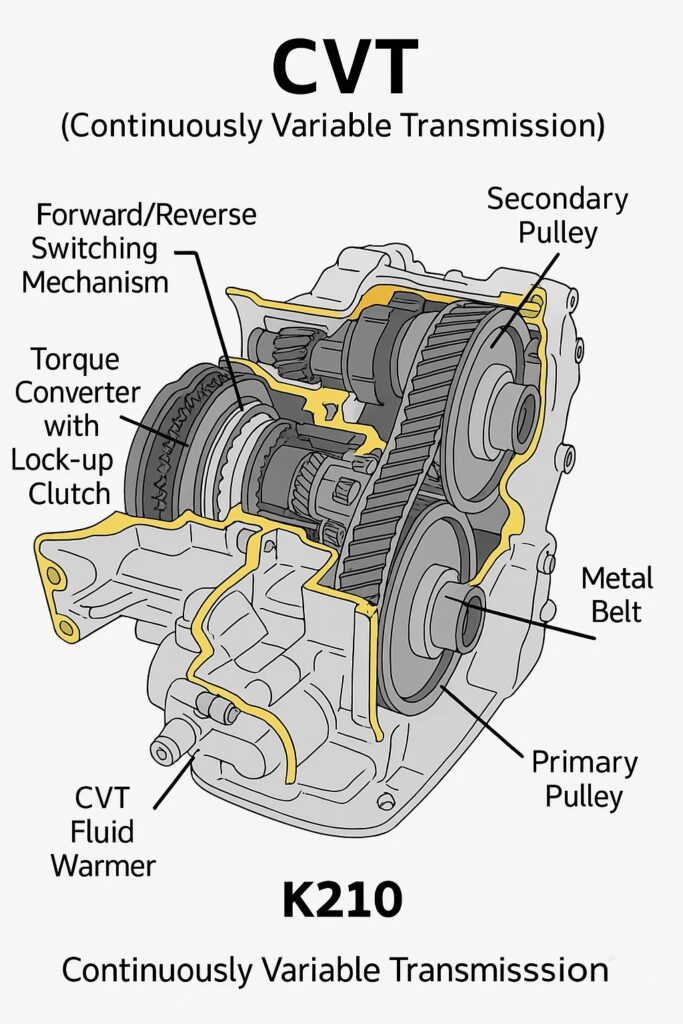

In contrast, a CVT eliminates fixed gears. It employs a system of two variable-diameter pulleys connected by a steel belt or chain. By continuously adjusting the diameter of these pulleys, a CVT creates an almost infinite number of gear ratios, keeping the engine in its most efficient RPM range. While brilliant for fuel economy, this design presents a unique set of challenges from a repair standpoint.

When Your Transmission Acts Up

Hard shifts, a loss of power, or weird noises from under the car are classic signs of transmission trouble. But what’s actually causing the problem depends entirely on what kind of transmission you have. Is it a traditional automatic or a Continuously Variable Transmission (CVT)?

When a vehicle with a traditional automatic transmission comes in with a complaint of harsh shifting or slipping, our diagnostic process typically involves checking the fluid level and condition, scanning for trouble codes, and performing pressure tests. Common culprits often include worn clutches, faulty solenoids, or issues with the valve body.

CVTs, on the other hand, have their own signature set of problems. We frequently see issues related to overheating, which can degrade the specialized CVT fluid and damage internal components. A shudder or hesitation during acceleration often points to a worn belt or pulleys. Diagnosing a CVT requires a deep understanding of its electronic controls and the ability to interpret specific diagnostic codes that are unique to this type of transmission. Generic code readers often miss CVT-specific faults, so we rely on factory-level scan tools to obtain the complete picture.

Maintenance is key for both transmission types, but the margin for error with a CVT is significantly smaller. Traditional automatics can sometimes tolerate delayed fluid service, but CVTs are far less forgiving of the condition and type of their fluid. Using anything other than the manufacturer-specified fluid can quickly lead to catastrophic failure. We always stress to our customers the importance of adhering to the recommended service intervals for their CVT.

When it comes to major repairs, the paths for these two transmissions diverge significantly. With a traditional automatic, a “rebuild” is a common and viable option. This involves disassembling the transmission, inspecting each component, replacing worn or damaged parts with new ones, and then reassembling it. This process can be labor-intensive, but it often gives a transmission a new lease on life.

Rebuilding a CVT, however, is a much rarer practice. The internal components, such as the belt and pulleys, are often not available as individual replacement parts in the aftermarket. Even if they were, the specialized tools and training required for a successful rebuild are not widespread. More often than not, a major CVT failure necessitates a complete replacement of the unit with a new or remanufactured one from the dealer. This reality has a significant impact on the final repair bill.

Problems You’ll Only Find (or Find More Often) in a CVT

Electrical and Sensor Faults

Your car’s computer controls the transmission, relying on a network of sensors to get the job done. When an input/output speed sensor or a temperature sensor fails, it can feel like a major mechanical breakdown, whether you have a CVT or a regular automatic.

Fluid Problems

Transmission fluid is the lifeblood of the system. If it gets low, contaminated, or burnt, it leads to slipping, overheating, and serious damage. Using the wrong type of fluid is just as bad, and CVTs are especially sensitive to this.

Solenoid & Valve Body Failures

Solenoids are small electronic parts that direct the flow of fluid inside the transmission. If one gets stuck or burns out, you might get harsh shifts or find the car won’t move at all. This can happen in any kind of automatic transmission.

Overheating

Nothing kills a transmission faster than heat. High temperatures can destroy the fluid and cook the internal parts, regardless of the type of transmission you drive.

Issues Unique (or Especially Severe) in CVTs

Belt or Chain Wear

Traditional automatics use planetary gears. CVTs rely on a steel belt or chain clamped between pulleys. Over time, this belt can slip or wear—causing the classic “rubber band effect,” where RPMs climb but speed doesn’t.

Pulley Wear and Bearing Failure

Because CVTs depend on moving pulleys under extreme pressure, worn pulley faces or failed bearings are common causes of whining, slipping, or total failure.

Fluid Sensitivity

While all transmissions need the right fluid, CVTs demand it. Using anything other than the OEM-specified CVT fluid can quickly lead to shudder, overheating, or belt damage. Even within a single brand, fluid specs can vary by model.

Calibration & Adaptation Requirements

Most CVTs don’t even have a dipstick. Checking fluid level often requires factory-level scan tools, performed at a precise temperature, with a calibration reset. This makes CVT service more dependent on specialized diagnostics than conventional automatics.

Why This Distinction Matters

Both conventional and CVT units fall under the category of “automatic transmissions,” but they operate on fundamentally different principles. This is why accurate diagnostics matter—because while they share the same end goal (shifting automatically without a clutch pedal), the repair strategies and tools required for each are unique.

If a general mechanic misdiagnoses a CVT issue as a traditional problem, they may replace the wrong part or even recommend replacing the entire unit unnecessarily. At Gold Coast Transmissions, we:

- Separate electrical vs. mechanical causes

- Use factory-level scan tools for calibration and diagnostics

- Rebuild CVTs in-house with OEM-grade components and fluids

This expertise allows us to repair CVTs properly—something most general shops aren’t prepared to do.

Our role as a transmission repair shop is to demystify these complex systems for our customers. We take the time to explain the fundamental differences between a traditional automatic and a CVT, the specific issues their vehicle is facing, and the repair options available. For our part, we continue to invest in the training and tools necessary to service and repair both of these evolving technologies, ensuring we can keep our customers safely on the road, no matter what kind of transmission is under their vehicle.

All transmissions share common failure points, but CVTs demand more precision, specialized tools, and training. That’s why we continue to invest in the expertise needed to keep our customers on the road—no matter what transmission they drive.