Most drivers expect a dead battery to cause a vehicle to not start. What they don’t expect is harsh shifts, torque-converter shudder, PRNDL flashing, limp mode, or a handful of “transmission” codes. Yet unstable power is one of the top reasons a healthy transmission behaves like it’s failing. We explain how voltage and grounds control shift quality, the failure patterns we see, and how we prove the root cause before any parts come off your car.

The Big Idea: Transmissions Are Computers with Hydraulics Attached

Modern transmissions use a Transmission Control Module (TCM) to pulse solenoids in milliseconds, set line pressure, and lock/unlock the torque converter. That precision depends on clean, stable power from three places:

- Battery – stable base voltage and reserve under load

- Alternator – steady charging without AC ripple (diode noise)

- Grounds – low-resistance paths between engine, body, TCM, and battery

If any of these go marginal, the TCM’s math is wrong—and so are your shifts.

What Low/Unstable Voltage Does (Mechanisms, Not Myths)

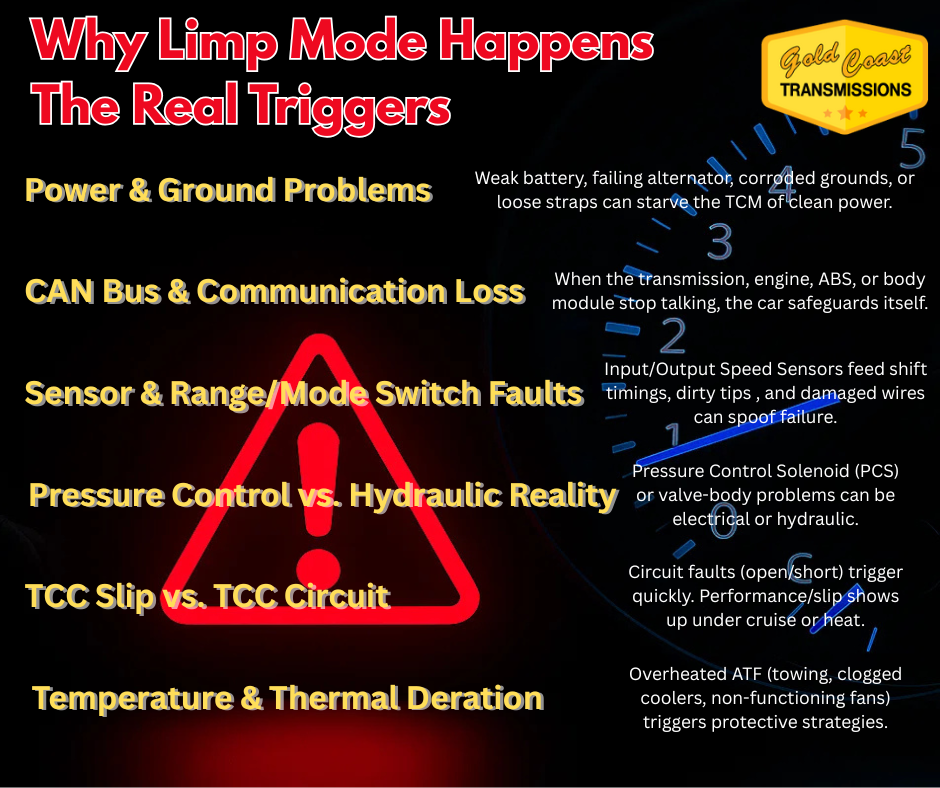

1) Solenoid Control Goes Sloppy

Solenoids are driven by PWM (pulse-width modulation). Undervoltage → less current → the valve doesn’t move as far/as fast → the TCM overcorrects → bang shifts, flares, or delayed engagement.

2) Sensors Lie (or Disappear)

- Hall-effect sensors (many speed & range sensors) need a clean 5V/12V supply. Undervoltage → dropouts → false P0715/P0720-type misfires.

- Reference-5V networks: A sagging regulator inside the PCM/TCM can drag multiple sensors down at once, creating “everything is bad” chaos.

3) Modules Stop Talking (Bus Off)

CAN/LIN modules will drop offline if voltage is noisy or low. That spawns U-codes (lost communication), cluster freakouts, and limp mode—even when the hydraulics are fine.

4) Torque Converter Shudder That Isn’t the Converter

Low voltage starves the TCC control driver. You feel shudder or slip, log P0741, and it looks like a bad converter—until proper charging and grounds make it vanish.

5) Adaptations Get Erased or Corrupted

A weak battery or jump-start voltage spike can reset learned pressure/adaptation tables. After that, expect harsh 1–2, odd 2–3 timing, and “range/performance” complaints until we perform a relearn.

Codes We Commonly See with Voltage/Ground Issues

P0711/P0715/P0720 – TFT/Speed sensor plausibility faults (supply or ground related)

P0562 – System Voltage Low

P0882 – TCM Power Input Low

U0101 / U0001–U0402 – Lost comms (TCM/ABS/BCM)

P0700 – Transmission control fault request (umbrella)

P0740/P0741 – TCC circuit/performance (often mimicked by low voltage)

The Hidden Villain: Grounds & AC Ripple

Grounds

A corroded or loose engine-to-chassis strap acts like a resistor. Under load, module grounds “float,” shifting sensor readings and solenoid targets. Result: ghost faults and erratic shifts.

Alternator Ripple

Failing diodes inject AC ripple onto the DC system. To modules, ripple looks like noise/jitter, which scrambles sensor edges and CAN timing. You get intermittent U-codes, random stalls, and shifting weirdness that follows electrical loads.

Start-Stop, AGM Batteries & Battery “Registration”

Many late-model vehicles use AGM batteries and an Intelligent Battery Sensor (IBS). After replacement, the system often requires battery registration/coding so the alternator charges correctly. Skip that, and you’ll chase chronic low-voltage behavior and premature battery wear—plus all the “transmission” symptoms above.

Aftermarket Add-Ons That Cause Trouble

- Big audio systems without proper wiring/grounds

- Remote starts and alarm taps on 5V reference or CAN lines

- LED/HID kits that backfeed noise into the system

We don’t remove your accessories; we isolate them and verify they aren’t polluting the power or the network.

Our Diagnostic Playbook (How We Prove It)

- Baseline Power Test

- Engine off/on voltage, loaded battery test, alternator output, and ripple check.

- Engine off/on voltage, loaded battery test, alternator output, and ripple check.

- Voltage-Drop Tests

- Positive and ground paths under load (starter, blower, heated seats on).

- Positive and ground paths under load (starter, blower, heated seats on).

- All-Module Scan + Freeze-Frame

- We correlate voltage at the moment each DTC set and map which modules went offline first.

- We correlate voltage at the moment each DTC set and map which modules went offline first.

- Live Data Reality Check

- Compare commanded vs. actual line pressure, ISS/OSS, TCC slip, and charging voltage in real time.

- Compare commanded vs. actual line pressure, ISS/OSS, TCC slip, and charging voltage in real time.

- Only then do we pressure-gauge, stall-test, or disassemble anything. If the power isn’t clean, then the data is not telling us the real story.

What Not to Do

- Don’t disconnect the battery with the engine running (voltage spikes).

- Don’t clear codes before capturing freeze-frame and module comm status.

- Don’t throw a converter/valve body at a car with obvious power problems.

When It’s Electrical vs. When It’s Mechanical

Electrical tells: Multiple U-codes, symptoms change with electrical loads, codes set at idle, issues improve after a restart or battery charge.

Mechanical tells: Repeatable flare/slip under heat/load with stable voltage, and pressure won’t meet command even when power is perfect.

Related Reading

- The Dreaded Limp Mode—What It Means and What It Doesn’t

- How Electrical Issues Affect Your Transmission

–

FAQ: Battery Voltage & Transmission Problems

Q: Can a weak battery really cause transmission issues?

Yes. A weak or unstable battery can starve the Transmission Control Module (TCM) of power, leading to harsh shifts, limp mode, or false trouble codes—even when the transmission itself is mechanically sound.

Q: What’s the difference between electrical and mechanical transmission problems?

- Electrical problems usually show up as multiple U-codes, shifting issues that change with electrical load, or limp mode that clears after a restart or charge.

- Mechanical problems are repeatable under heat/load and won’t improve when power is stable.

Q: I replaced my battery, but still get transmission codes—why?

Many late-model vehicles require battery registration after replacement. If skipped, the charging system may undercharge or overcharge, leading to chronic low-voltage symptoms that mimic transmission failure.

Q: Which engine/transmission codes point to voltage or ground issues?

Common ones include:

- P0562 (System Voltage Low)

- P0882 (TCM Power Input Low)

- U0101/U0001–U0402 (Lost Communication)

- P0740/P0741 (Torque Converter Circuit/Performance)

- P0715/P0720 (Speed Sensor faults)

Always check freeze-frame voltage before assuming a hard transmission failure.

Q: Can alternator problems cause shifting issues?

Absolutely. A failing alternator diode creates AC ripple on the system, which confuses sensors and modules. This can trigger random stalls, U-codes, and shift quality changes tied to electrical loads.

Q: Do aftermarket accessories affect transmission behavior?

Yes. Poorly wired audio systems, remote starters, alarms, or lighting kits can backfeed noise into 5V reference or CAN lines, leading to false transmission codes and erratic performance.

Q: How do you confirm it’s electrical before opening the transmission?

We follow a diagnostic playbook:

- Test battery/charging health under load

- Check voltage drop on positive and ground paths

- Scan all modules with freeze-frame data

- Compare live line pressure, speed sensors, and charging voltage

If power isn’t clean, the data can’t be trusted. Only after proving stable voltage do we move to mechanical testing.