You’re cruising, then all of a sudden, your car won’t shift. It’s stuck in one gear, and the dash lights up like a Christmas tree. That’s limp mode. It sounds catastrophic, but it’s your vehicle’s way of protecting the powertrain until a proper diagnosis can be done.

Here’s how limp mode works, what commonly triggers it, and how we separate a real fix from an expensive misdiagnosis.

What Limp Mode Is (and Isn’t)

It is: A built-in failsafe strategy for your vehicle. The control modules (PCM/TCM) detect a fault and lock the car into a limited operating state—typically 2nd or 3rd gear, reduced power, no overdrive/TCC lockup—so you can get to safety or a shop.

It isn’t: An automatic death sentence for your transmission. Many limp mode cases trace back to electrical, sensor, or communication problems—not a destroyed transmission.

Quick Triage: What To Do

Ease off. Don’t force highway speeds when driving in limp mode—keep it gentle and steady.

Restart once, safely. Some platforms clear limp on key cycle; if it returns, stop guessing.

Note the symptoms. Stuck gear? Flashing PRNDL? Erratic speed? Take a photo of the dashboard and signs.

Call us. We’ll book a full diagnostic and explain findings in plain English.

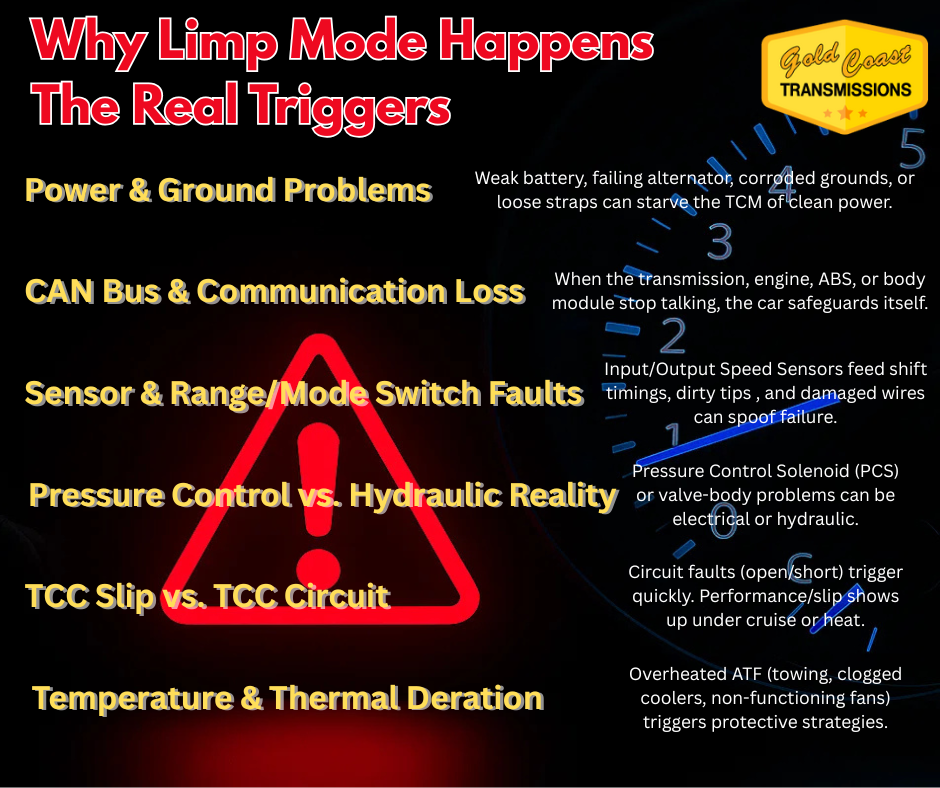

Why Limp Mode Happens: The Real Triggers

Power & Ground Problems (The Hidden Culprit)

- A weak battery, a failing alternator, corroded grounds, or loose straps can starve the TCM of clean power.

- Symptoms: PRNDL flashing, random “U-codes,” harsh engagements, and modules dropping offline.

- Want the bigger picture? See how electrical issues affect your transmission.

CAN Bus & Communication Loss

- Modern cars are networks. If the transmission, engine, ABS, or body module stop talking, the car safeguards itself.

- Clues: Multiple warning lights, scan tool shows “Lost Comm” with TCM/ABS/BCM.

- We verify by comparing wheel speed (ABS), output speed, and vehicle speed live.

Sensor & Range/Mode Switch Faults

- Input/Output Speed Sensors (ISS/OSS) feed shift timing; dirty tips, broken reluctors, or damaged wires can spoof failure.

- Range/Mode (PRNDL/IMS) reporting the “wrong” gear will force failsafe.

- Paired issues with MAF/TPS/ECT can trick the transmission into bad timing decisions.

Pressure Control vs. Hydraulic Reality

- Pressure Control Solenoid (PCS) or valve-body problems can be electrical (coil/driver) or hydraulic (stuck valves, varnish, debris).

TCC Slip vs. TCC Circuit

- Circuit faults (open/short) trigger quickly; performance/slip shows up under cruise or heat.

- Low voltage can mimic TCC slip; a converter isn’t guilty just because a code says “TCC.”

Temperature & Thermal Derate

- Overheated ATF (towing, clogged coolers, non-functioning fans) triggers protective strategies.

- A false “overheat” signal from a damaged TFT circuit can also force limp.

- Related deep dive: What happens when coolant or water hits your transmission circuits?

Misdiagnosis: Why Parts Swapping Fails

Codes point to where a problem was detected—not always why. Replacing a sensor, solenoid, valve body, or even the whole transmission without power/ground checks, network testing, and pressure verification is how people spend thousands and still limp home.

How We Diagnose Limp Mode (Our Playbook)

Power & Charging Check

Clean 12.6V off / 13.8–14.4V running. If the voltage is wrong, everything after is noise.

Scan All Modules + Freeze-Frame

We don’t stop at the engine/trans. ABS, body, and gateway modules tell the network story.

Harness & Connector Inspection

We’re looking for ATF wicking through connector sleeves, water intrusion, chafed looms, and green crust on pins.

Live Data + Commanded Tests

Compare commanded vs. actual line pressure, ISS/OSS plausibility, TCC slip trends, and gear ratio math.

Hydraulic Verification

If electronics pass, we test hydraulics (manual pressure gauge, stall test, adaptation status).

Software Updates & Relearns

After repair, we perform TCM/PCM updates and adaptive relearns—skipping this causes fresh harsh shifts and “new” codes.